I've come across quite a few used DMG-01s, and it seems to be a common problem that there's dead columns or rows of pixels on the LCD. I've looked at YouTube but nothing there as far as fixes have really given me any confidence. Does anybody know a good, solid way to fix this issue?

There are some talks that heathing the cabel (near or itself) might help in the problem, but i'm not the best to talk about it. There are some threads somewhere too (here or at 8bc, can't check now)

horizontal lines and verticle lines are 2 diffrent problems.

it has been discussed like mad here:

(sorry for linking but...)

https://8bc.org/forums/viewtopic.php?id=5679

i have done this a few times, on different gameboys.

and it solved all the HORIZONTAL lines, but had no effect on verticle ones.

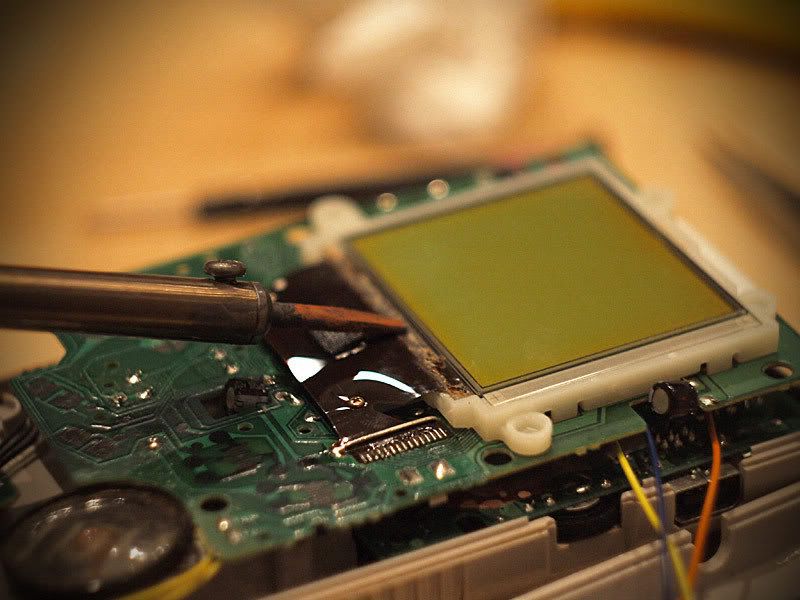

you need to take off the foam piece at the top of the screen

cable, and (VERY GENTLY) heat it w/ a soldering iron.

i actually rubbed it pretty quickly a number of times. i had to

keep plugging + unplugging the cable to check my work. DONT

REATTACH THE CABLE WHILE THE PLASTIC IS STILL HOT!

hope this helps...

Last edited by xero (May 31, 2011 8:24 pm)

I did the vertical line fix with my DMG on. Pumped the contrast up so I could see what was missing and went to town. I had to hold the soldering iron there a little bit. Definitely wasn't just lightly touching it. Worked for me.

i actually rubbed it pretty quickly a number of times. i had to

keep plugging + unplugging the cable to check my work. DONT

REATTACH THE CABLE WHILE THE PLASTIC IS STILL HOT!hope this helps...

It won't harm anything if you turn it on while it's hot. You can even do this while the unit is running, which is actually how you should do it to avoid over heating the ribbon cable. Doing this is actually more likely to wreck your DMG because that ribbon cable can only handle so much removing/reinserting.

I found that actually adding solder helps incredibly. Remove all the adhesive so you don't gunk up the tip though. But once you add solder, the heat is distributed more evenly, and I find I can always repair dead vertical lines if I use this method. The solder won't adhere to the cable, so it can be easily removed afterward.

Okay...so I need a soldering iron. Hmm.

I agree with you here ape. I used a small dab of solder to get the best results.

The soldering iron trick worked like a champ! I was a bit worried since it took a while for it to work but I was able to restore ALL my dead vertical lines. Very cool!

The soldering iron method worked for me too! At first I thought I really messed it up as more lines around the dead ones flickered but as it cooled the lines all came back to life and it was fine n dandy ![]() I found rolling the iron up and down instead of side to side helps fix the columns.

I found rolling the iron up and down instead of side to side helps fix the columns.

Part of me says "Awesome! Someone used the search function." Then another part of me says "NECROPOST!!"

Part of me says "Awesome! Someone used the search function." Then another part of me says "NECROPOST!!"

Eh. Whatever keeps Saskrotch from trolling you.

Hi,

It works fine also with hot air from rework station, but effectively not a lot of people got one .. but using a hot air rework station it a very safe method (if you don't set your air temperature more than 150 deg Celsius) and you won't get any solder iron "mark" on the ribbon cable.

you can take a look here : http://noizeinabox.blogspot.co.uk/2012/ … ework.html

Last edited by xray303 (Jul 10, 2012 8:34 am)

Eh. Whatever keeps Saskrotch from trolling you.

you guys realize trolling is more specific than just being an asshole right?

I found that actually adding solder helps incredibly. Remove all the adhesive so you don't gunk up the tip though. But once you add solder, the heat is distributed more evenly, and I find I can always repair dead vertical lines if I use this method. The solder won't adhere to the cable, so it can be easily removed afterward.

I agree with you here ape. I used a small dab of solder to get the best results.

Solder is the most important part of the soldering iron—you have to keep the tip tinned and "wet" at all times for the iron to effectively transfer heat to the work, and it's essential for the "wetting" action of a good solder joint.

So, keeping the tip tinned makes the iron transfer heat to the ribbon cable more effectively, and it also keeps you from oxidizing the shit out of your solder tip and ruining it, which I did the first time I ever reflowed a DMG ribbon cable like this.

basspuddle wrote:Eh. Whatever keeps Saskrotch from trolling you.

you guys realize trolling is more specific than just being an asshole right?

there does seem to be a lot confusion about that lately