Backstory: I recently purchased 2 dmg01 gameboys to add to my collection, which are somewhat broken now.

Which is great and all but the first one that I received I spliced the ribbon cable that is directly underneath the thin rubber gasket with a razor blade while trying to remove the polarization and emulsion layer. Which lead me to purchase another unit today. The gameboy was in very good condition no external damage or dead pixel or lines, I was so exited.

I've spent the whole entire day messing with this thing and I'm at my wits end.

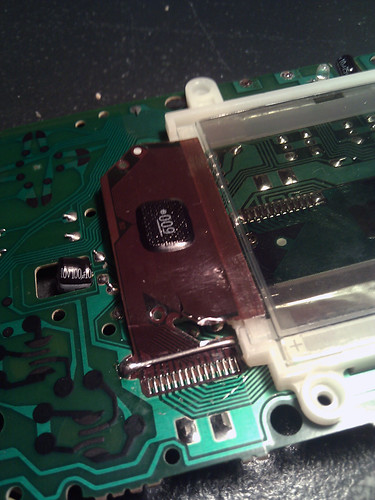

I solder the backlight into the second one and then power it on, the screen only has one horizontal line at the top which I don't really mind to much but the the entire screen is completely white. The contrast wheel isn't any help, it doesn't function any longer besides slightly changing the contrast of the horizontal line. The gameboy is still functioning as it starts up and the little ping sounds and the game starts but still nothing but a blank screen.

I really need help is there anything I can do to fix this?